Checking the HC residence and starting thepiping cleaning automatically. Checking zero gas automatically(optional). Zeroing sensors and checking sensorsstatus periodically. Cleaning the piping every time before shutdown. Warming up automatically

Checking the HC residence and starting thepiping cleaning automatically. Checking zero gas automatically(optional). Zeroing sensors and checking sensorsstatus periodically. Cleaning the piping every time before shutdown. Warming up automatically Ability of communicate with a citysVehicle Emission control andManagement System or VID. It is possible to monitor testing procedureby authority through internet. (optional). All monitoring requirements can beimplemented by on-line module.

Ability of communicate with a citysVehicle Emission control andManagement System or VID. It is possible to monitor testing procedureby authority through internet. (optional). All monitoring requirements can beimplemented by on-line module.

| Parameter | Middle duty | Heavy duty | Twin axle |

| Model | Ca-Dyno | Me-Dyno | Mh-Dyno/T |

| Axle load | 3,000 | 10,000 | 10,000 |

| Roller diameter (mm) | 217 | 217 | 420 |

| Roller spacing (mm) | 436 | 436 | 670/1350 |

| Min. Track length (mm) | 760 | 750 | 780 |

| Max. Track length (mm) | 2540 | 2710 | 2740 |

| Max Power absorbed (KW) | 140-180 | 270-330 | 2X350 |

| Max. Torque absorbed (Nm) | 1750 | 3300 | 2X3300 |

| Motor Power (KW) | 5.5 | 7.5 | 15 |

| Base inertia (kg) | 908 | 908 | 1460 |

| Speed test range (km/h) | 120 | ||

| Speed test accuracy (km/h) | ±0.2 | ||

| Torque test accuracy | 2% | ||

| Drive | PWM+GBT | ||

| Port | RS232C | ||

| Dimision L×W×H(mm) | 3980X700X370 | 4300X1410X550 | 4800X2650X550 |

| Gas | Measuring Range | Resolution | Accuracy |

| HC | 0-2000X10-6 2001-15000X10-6 1500130000X10-6 | 1X10-6 | ±4X10-6 abs or ±3% ±5% ±8% |

| CO | 0.00-10% 10.01-15.00% | 0.01% | ±0.02% abs or ±3% ±5% |

| CO2 | 0.00-16% 16.01-20.00% | 0.01% | ±0.3% abs or ±3% ±5% |

| NO | 0-4000×10-6 4001-5000x 10-6 | 1×10-6 | ±25X10-6 abs or ±4% ±5% |

| O2 | 0.00-25% | 0.01% | ±1% or ±3% |

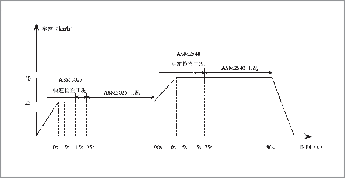

To test gasoline engine emission by procedures ASM (Acceleration simulation mode) IG195 TSI (wo speeds idle) To test diesel engine emission by procedures Lugdown FA(Free acceleration)All functions selected would be implemented by selection of differentsub-assemblies. accessories and software modules

To test gasoline engine emission by procedures ASM (Acceleration simulation mode) IG195 TSI (wo speeds idle) To test diesel engine emission by procedures Lugdown FA(Free acceleration)All functions selected would be implemented by selection of differentsub-assemblies. accessories and software modules| Parameter | Data |

| Measuring range | N, 0~99.9% K,0~15/m |

| Resolution | N, 0.1% K,0.01/m |

| Accuracy | ±2% |

| Stability | ±1%h |

| Working environment | Temp. 5~40℃ Humidity 0~90% Baro 86~106kPa |

| Power supply | AC220V±10%, 50Hz ±1% |

| Output | RS232C (baud rate 1200,2400,4800,9600,19200) |

| Weight | ~13kg |

| U3 console body, corrosion free surface by powder spray. | |

| Computer system | Industrial PC, Plll 1GHZ or more, 128M memory, 40G hard driver, 10/100MEthemet Port. 17 color fat CRI. Laserjet A4. |

| Communication Protocol | TCP / IP |

| Optional | Tamper recognizing device |

| Power supply | 220VAC 50HZ 2KW |

| Air pressure | 10.6-0.9 MPa |

| Operation temperature | 5-40°C |

| Operation humidity | < = 90 % ( No condense ) |

| Dimension | 900X600X1050 mm |

| Parameter | Measuring Range | Accuracy |

| Temperature (°C) | -25 -+85 | ±1.5 |

| Humidity (RH) | 5%-99% | ±3.0% |

| Air pressure (kpa) | 50-110 | ±3% |